[The following is the HTML version of the original report which can be also download as PDF here.]

1st June, 2015

Submitted to

Ministry of Environment, Forests and Climate Change,

Govt. of India

Copyright Info:

This document is released under Creative Commons Attribution Share Alike 2.5 India License

You are free to use this document copy and redistribute the material in any medium or format; remix, transform, and build upon the material for any purpose. You must give appropriate credit, provide a link to the license, and indicate if changes were made. You may do so in any reasonable manner, but not in any way that suggests the licensor endorses you or your use.If you remix, transform, or build upon the material, you must distribute your contributions under the same license as the original. You may not apply legal terms or technological measures that legally restrict others from doing anything the license permits.

About the Document

The Ministry of Environment, Forests and Climate Change, Government of India has published a draft notification for emission standards for coal based thermal power plant under the Environment (Protection) Act, 1986 (29 of 1986). The said draft notification was made available online on Ministry’s website[1] on May 15th, 2015 for public comments and suggestions. Accordingly, this document proposing suggestions/comments is prepared and being submitted for the Ministry’s perusal and consideration for preparation of the final

notification

Vindhyan Ecology and Natural History Foundation is a registered trust (2012) in Indian city of Mirzapur, Uttar Pradesh. VENHF’s environment advocacy and activism work and the enormous popularity of its Vindhya Bachao campaign have profoundly changed the conservation perspective in the region. Its efforts have created a generation of environment-conscious citizens who understand as never before the way excessive exploitation of natural resources affect the forests, rivers, climate, food and public health. All the members and advisors of VENHF are associated voluntarily. VENHF is also member of Global Call for Climate Action Network, a coalition of more than 450 organizations in more than 70 countries with a shared goal — a world safe from runaway climate change.

Debadityo Sinha is an environmentalist and has been working extensively for protection of environment and forests in Vindhyan range. He holds a Master’s Degree in Environment Science and Technology from Banaras Hindu University and Bachelors in Zoology from University of Delhi.

INDEX OF CONTENTS

A. On Emission Standards for PM

B. On Emission Standards for SOx

C. On Emission Standards for NOx

D. On Emission Standards for Hg

E. On Selection of Categories of Emission

G. Standards Needed to be Added

Annexure (Copy of the Draft Notification)

A. On Emission Standards for PM

|

MOEFCC Proposed: |

|||||

|

Pollutants |

Older Units |

Older New |

Future |

||

|

before December 31, 2003 |

After 2003 to 2006 |

from January, 2017 |

|||

|

<500 MW |

≥ 500 MW |

<500 MW |

≥ 500 MW |

|

|

|

PM |

100 mg/ Nm3 |

50 mg/ Nm3 |

30 mg/ Nm3 |

||

Comments:

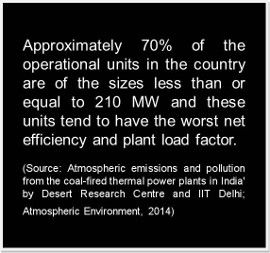

The standard of 30 mg/ Nm3 is a welcome step as compared to previous emission standard of 150 mg/ Nm3 but still it is inadequate; the relaxation of older units up to 100 mg/ Nm3 and 50 mg/ Nm3 is not acceptable as emission control for PM are achieved by same technologies like coal beneficiation, ESP, Bag Filter or Cyclone.

30 mg/ Nm3 as the emission standard seems to be in line with emission standards in countries like China. But it is also important to know that in China no new smaller units are allowed and most of their existing small plants have been decommissioned. The PM emission standard for thermal power plants in key regions is 20 mg/ Nm3. Also, China has a robust plan to switch from Coal to Natural Gas for power generation[2][3] which means their emission from coal even if not reduced in coming future, but the rate of increase in emissions will be significantly reduced.

Similarly, the dust emission standards in EU is 30 mg/Nm3 for units less than 100 MW, 25 mg/ Nm3 for units 100-300 MW and 20 mg/ Nm3 for units above 300 MW.

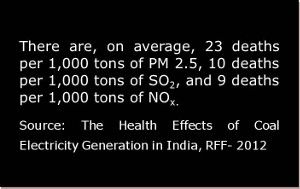

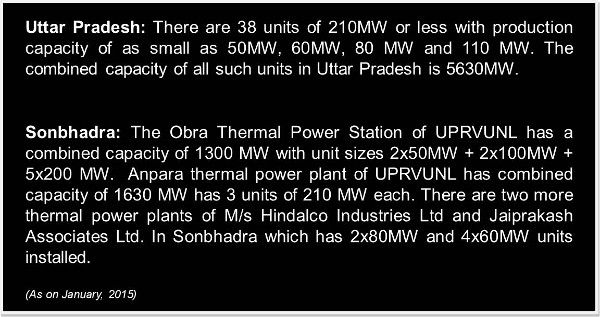

It is further submitted that given the high ash content of coal and the fact that number of indigenous coal based thermal power plants are located sequentially in concentrated pockets like Singrauli-Sonbhadra, Raigarh-Korba and many other such places, the standards of even 30 mg/ Nm3 will prove to be not serving the purpose. Also, the population size and density of our nation makes its people more vulnerable to exposure. The efforts must be made to reach zero PM emission. However, in practice, 20 mg/ Nm3 are followed in some countries, and India must adopt such strictest standard possible.

B. On Emission Standards for SOx

|

MOEFCC Proposed: |

|||||

|

Pollutants |

Older Units |

Older New |

Future |

||

|

before December 31, 2003 |

After 2003 to 2006 |

from January, 2017 |

|||

|

<500 MW |

≥ 500 MW |

<500 MW |

≥ 500 MW |

|

|

|

SO2 |

600 mg/ Nm3 |

200 mg/ Nm3 |

- |

200 mg/ Nm3 |

100 mg/ Nm3 |

Comments:

The emission of SO2 is one of the major environmental pollution from thermal power plants and a major concern not only for health but its significant impact on agriculture[4]. Relaxation of older and smaller units to continue emit 6 times more (600 mg/ Nm3) than newer plants (100 mg/ Nm3) will not solve the problem as most of the older and smaller units have less efficiency and are the biggest emitter of SO2. Therefore, the limits which have been prescribed for the older units cannot be justified. Similarly, the absence of standards for units in category ‘after 2003-2006’ for less than 500 MW capacity is not justified.

For e.g. European Union has delineated the units as per Schedule I (units before January, 2016) and Schedule II (later January 2016)

Even if we consider the standards by the European Union, (which is very much relaxed and not the best) the maximum emission for units up to 100 MW for Schedule I and Schedule II units is 400 mg/ Nm3. For the older units which were in operation before 2003, the emission standards are relaxed upto 800 mg/ Nm3. However, this figure of 800 mg/ Nm3 should be read with the condition as mentioned in the EUROPEAN UNION (LARGE COMBUSTION PLANTS) REGULATIONS 2012, Schedule I, Para 2 as follows:

Combustion plants, using solid fuels which were granted a licence before 27 November 2002 or the operators of which had submitted a complete application for a licence before that date, provided that the plant was put into operation no later than 27 November 2003, and which do not operate more than 1,500 operating hours per year as a rolling average over a period of 5 years, shall be subject to an emission limit value for SO2 of 800 mg/ Nm3

It is a well-accepted fact that standards followed by European Unions for thermal power plants are far below the global standards followed in countries like China, Japan and U.S. At this juncture when we are prescribing our standards, we must follow the world’s best practices and regulations.

Therefore, we suggest that all existing thermal power plants must comply with 200 mg/ Nm3 with a mandate to reach the target of 100 mg/ Nm3 within 2 to 3 years and the 100 mg/ Nm3 emission standard for newer plants shall be extended to all existing thermal power plants in key areas which may be classified based on number of thermal power plants or other polluting industries in vicinity and ecologically sensitive areas like places of regular gathering, large population, forests etc.

It is also a matter of fact that until FGD (Flue Gas Desulphurization) units are installed, the emission reduction of thermal power plants may not be achieved. Very few thermal power plants are recommended for installation of FGD and it is yet to be made mandatory by law for all TPPs. It is a high time now, to make installation of FGD mandatory pollution control equipment. There are several thermal power plants which are operating with FGD which itself shows its feasibility and economic viability. The FGD not only helps in significantly reducing SO2 but an array of toxic heavy metals like Hg (Mercury) which are usually not trapped by ESP and also reduce the efficiency of filters.

Therefore, we strongly suggest that installation of FGD must be made mandatory. The units which are commissioned in recent years have provisional space for installation of FGD which won’t take much time to get them installed.

The ‘older new’ units which do not have space allocations for FGDs must be mandated to go for ‘desulphurization of coal’ before combustion and adopt other methods of reduction of sulphur dioxide emission through other in-combustion methods. The older units where it is impossible to bring down the emission levels of SO2 must be decommissioned and upgraded to latest technology units.

C. On Emission Standards for NOx

|

MOEFCC Proposed: |

|||||

|

Pollutants |

Older Units |

Older New |

Future |

||

|

before December 31, 2003 |

After 2003 to 2006 |

from January, 2017 |

|||

|

<500 MW |

≥ 500 MW |

<500 MW |

≥ 500 MW |

|

|

|

NOx |

600 mg/ Nm3 |

300 mg/ Nm3 |

100 mg/ Nm3 |

||

Comments:

The value of 100 mg/Nm3 for newer units is encouraging and appreciable and shows the MOEFCC’s commitment towards sustainable development principle. However, again the value of 600 mg/ Nm3 for older units is without any justification and will not solve the purpose as discussed in previous sections.

The European Union standards which is widely criticized for its relaxed attitude towards emission standards othermal power plant prescribes 200 mg/ Nm3 for all units more than 100 MW and for older units, the standards are relaxed but with the condition stated in the EUROPEAN UNION (LARGE COMBUSTION PLANTS) REGULATIONS 2012, Schedule I, para 2 which is as follows:

Combustion plants using solid or liquid fuels with a total rated thermal input not exceeding 500 MW which were granted a licence before 27 November 2002 or the operators of which had submitted a complete application for a licence before that date, provided that the plant was put into operation no later than 27 November 2003, and which do not operate more than 1,500 operating hours per year as a rolling average over a period of 5 years, shall be subject to an emission limit value for NOx of 450 mg/ Nm3 . Combustion plants using solid fuels with a total rated thermal input greater than 500 MW, which were granted a licence before 1 July 1987 and which do not operate more than 1,500 operating hours per year as a rolling average over a period of 5 years, shall be subject to an emission limit value for NOx of 450 mg/ Nm3

China has stricter rules and it mandates 100 mg/ Nm3 for all thermal power plants except those units which are built before January, 2004 as 200 mg/Nm3. The Chinese standard seems to be most sustainable approach towards reduction of NOx and may be applied in Indian standards.

D. On Emission Standards for Hg

|

MOEFCC Proposed: |

|||||

|

Pollutants |

Older Units |

Older New |

Future |

||

|

before December 31, 2003 |

After 2003 to 2006 |

from January, 2017 |

|||

|

<500 MW |

≥ 500 MW |

<500 MW |

≥ 500 MW |

|

|

|

Hg |

- |

0.03 mg/ Nm3 |

0.03 mg/ Nm3 |

0.03 mg/ Nm3 |

|

Comments:

The emission standard proposed for Mercury is without any scientific assessment and will not serve the purpose of reduction of mercury emitted by the thermal power plants, and will also prove to be ineffective in reducing the mercury emissions. The proposed emission standards are far more than what the thermal power plants are emitting. No standards prescribed for older units less than 500 MW is not justified and they must be included.

CIMFR 2014 study on thermal power plants in India[5] revealed that the mercury content in FLUE GAS to be 14.84 µg/ Nm3(0.01484 mg/ Nm3) in Talcher STPP of NTPC and 4.24 ug/NM3 (0.00424 mg/Nm3) in Budge Budge CESC which is itself quiet high than the proposed standards. A summary of the mercury emitted in flue gas as recorded in the study is as follows:

|

Power Plant |

Unit Capacity |

Hg in Flue Gas (ug/ Nm3) |

Hg in Flue Gas (converted to mg/Nm3) |

|

Talcher STPP, NTPC |

500 MW |

14.84 |

0.0148 |

|

Korba (W) CEB |

210 MW |

11.50 |

0.0115 |

|

Budge Budge CESC |

250 MW |

4.24 |

0.00424 |

It is also submitted that the concentration of mercury varies in different combustible products and the highest fraction is present in flue gas than fly ash. The table for Distribution of Mercury in Flue Gas emission is summarized as follows:

|

Power Plant |

Unit Capacity |

Speciation % |

% of Hg emitted (average |

|

|

Hg2+ (Oxidized) |

Hg0 (Elemental) |

|||

|

Talcher STPP, NTPC |

500 MW |

30.8 |

60.8 |

81 |

|

Korba (W) CEB |

210 MW |

11.3 |

88.1 |

61 |

|

Budge Budge CESC |

250 MW |

41.6 |

58.1 |

27 |

|

Singrauli STPP |

200 MW/ 500 MW |

30.08 |

68.98 |

73 |

|

Vindhyachal STPP |

6 x 210 MW/ 2 x 500 MW |

30.09 |

69.26 |

60 |

|

Rihand STPP |

2 x 500 MW |

38.20 |

56.61 |

48 |

(For details, see the original report[6])

IMPORTANT NOTE:

The proposed standard of 0.03 mg/ Nm3 is approx. 73 times more relaxed than the U.S. EPA standard of 0.003 lb/GWh which comes out 0.00041 mg/ Nm3 for Indian Thermal Power Plants (See the calculation in the box below). The proposed standard is also several times more than the amount of Mercury presently emitted by the thermal power plants through flue gas.

Conversion of Emissions Standards based on U.S. EPA Standard:

Average Energy Efficiency of Coal-based Thermal Power Plants in India (CSE, 2015[7]): 33.7%

The same study shows that the highest efficiency was found to be 38.1%

Therefore, for production of 1 MWh, coal containing energy equivalent to 2.63 MWh need to be burnt on an average at an efficiency of 38.1 % (under best scenario)

Using conversion factor of

1 MW = 3.6 GJ, = 2.63 x 3.6 = 9.47 GJ/MWh

And specific flue gas volume rate[8] for coal combustion (dry 6% excess O2) = 350 Nm3/GJ

Flue gas volume per unit electricity output= 9.47 GJ/MWh x 350 Nm3 /GJ = 3314.5 Nm3/MWh

U.S. Standard: 0.003 lb/GWh or 1.361 g/GWh or 1361 ug/MWh

Conversion of emissions of thermal power plant if complied with US. Standard:

1361 ug/MWh ÷ 3314.5 Nm3/MWh = 0.41 ug/Nm3 or 0.00041 mg/ Nm3

Therefore, the emission standards for Mercury needs serious reconsideration of the Ministry and it should be proposed in such a manner that the mercury emission is reduced and not encouraged to emit more. The standard emission of mercury at 0.00041 mg/Nm3 must be implemented for the fact that toxicity of Mercury even in minute concentrations is hazardous.

E. On Selection of Categories of Emission

|

MOEFCC Proposed: |

|||||

|

Pollutants |

Older Units |

Older New |

Future |

||

|

before December 31, 2003 |

After 2003 to 2006 |

from January, 2017 |

|||

|

<500 MW |

≥ 500 MW |

<500 MW |

≥ 500 MW |

|

|

The draft notification has categorized the emission standards as above three categories which shall meet the emission standards as follows:

1. Units installed before December 21, 2003 (shall meet limits within 2 years from date of notification)

Comments: the basis of selection of category is not clear. The standards should also consider the ‘years of operation’ as every thermal power units have a design life.

2. Units installed after 2003 to December 31, 2006 (shall meet limits within 2 years from date of notification)

Comments: ‘After’ or ‘between’ needs to be clarified. There must be some reasons which are known to the Ministry, but we could not appreciate this categorisation and hence seek clarification. This category also creates much confusion on the thermal power units commissioned after 2006 to 2017. Will there be no standards for them?

3. Units to be installed from January 1, 2017 (includes all units which have been accorded environmental clearance and are under construction)

Comments: This delay till January, 2017 is again a secret, reasons best known to the Ministry. However, I feel the notification must be brought sooner and emission standards must be in effect on all newer installations from the date of notification. Owing to the commitments of the government for quick clearances to projects to ensure developmental projects meet minimum hurdles, the standards should be notified without any further delay.

The Suggested Categories are

1. Newer Units to be operational from 2015 or date of the notification (Schedule I)

2. Existing Units operational between 2004 till 2015 (or till date of notification) (Schedule II)*

3. Existing units before 2004 (Schedule III)*

4. Existing units which completed their designed years of operation (Schedule IV)

(*Though the exact reason for selecting 2004 a landmark year by MOEFCC is not known, but we assume that Ministry must have kept in mind the major technological differences in thermal power units built prior and post 2004.)

F. On Water Consumption

|

MOEFCC Proposed: |

||

|

1.All plants with once through cooling (OTC) shall install cooling tower (CT) and achieve specific water consumption max. 4m3/MWh within 2 years period from the date of notification |

2.All existing CT-based plants shall reduce specific water consumption upto maximum of 3.5 m3/MWh within 2 years period from date of notification. |

3. New plants to be installed after January 01, 2017 shall meet specific water consumption maximum of 2.5 m3/MWh and achieve zero liquid discharge. |

It is a very good step to make it mandatory for all power plants to install Cooling Towers. The previous guideline issued by MOEF, 1999 all thermal power plants commissioned after June 1, 1999 was required to install cooling towers. But, the consumption value of max. value of 4m3/MWh is not understandable. If they are mandated to install new cooling towers, then why not the standards should be same for the older and newer units and zero liquid discharge also made mandatory for all? Additionally, the water consumption in thermal power plants does not depend only on cooling tower but also on the type of cooling tower such as wet cooling, dry cooling, Cycles of Concentration (COC) and also on the ash disposal mode among several other factors which needs to be considered.

The water consumption standards are also very relaxed and lower than what CEA (Central Electricity Authority) recommends[9]. The CEA recommendations are as follows:

|

Description |

In Land Plants |

Sea Water Based Coastal Plants (fresh water requirement |

|

|

Plants with wet cooling tower |

Plants with dry cooling tower |

||

|

Water Requirement for 1st year of plant operation |

3.6 (fly ash disposal in wet slurry mode) |

0.75 (fly ash disposal in dry mode right) |

0.4 |

|

3.0 (fly ash disposal in High Concentration Slurry Disposal mode) |

0.90 (fly ash disposal in HCSD) |

||

|

Water Requirement during subsequent period |

3.0

(fly ash disposal in wet slurry mode) |

0.55

(fly ash disposal in dry mode right) |

|

The above plant water requirements are for normal sources of raw water with COC of 5 for CW system. In case, treated sewage water or high TDS water is used as source for raw water or plant is required to be provided with FGD unit, the plant water requirement could be higher which needs to be worked out on case to case basis. In some cases, it may be possible to increase COC of CW system above 5.0 based on quality of raw water and feasibility of cooling water treatment. In such case, plant consumptive water would reduce according to CT blow down reduction.

The Experts Appraisal Committee while giving Environment Clearance has been prescribing the CEA norms for water consumption and a minimum COC of 5.0 for new thermal power plants. However, this COC of 5.0 must be not the maximum criteria as higher COC is achievable by some technological intermediations. Therefore, the COC number must be standardized as per the world’s best practices.

Overall, the water consumption standards need to be revised for stricter and based on technical advancements available. This is very much important because, most of the thermal power plants are located near dams, rivers and big reservoirs and pose additional burden on our agricultural and drinking water needs. India is already a water-stressed country with one of the highest growing population. This is bound to increase water demand for all sectors. Experts have already warned that by 2025 India’s water demand may surpass the water supply and in coming decade the nation may become ‘water scarce’.

CSE[10] in its report of 2015 has claimed that global best specific water consumption in thermal power plants is 1.6 m3/MWh (USA – 2 m3/MWh and China 2.5 m3/MWh) and the India best is JSWEL, Toranagallu at 2 m3/MWh. Therefore, 2 m3/MWh can be the uniform standard for maximum specific water consumption in all thermal power plants.

Additionally, zero liquid discharge must be made mandatory for all thermal power plants. This is achievable as all the thermal power plants with cooling towers can achieve zero discharge by recycling of the water.

G. Standards Needed to be Added

· The standards missed out several important air emissions like Lead, Selenium, Arsenic, Beryllium, Cadmium, Chromium, Cobalt, Lead, Manganese, Acid Gases (Hydrogen Chloride and Hydrogen Fluoride), PAHs (Polycyclic Aromatic Hydrocarbons) and VOCs (Volatile Organic Compounds), Dioxins and Furans which are hazardous air pollutants emitted from coal based power plants and are known for serious health impacts and affecting our ecology. The notification is silent on these impacts. However, there are scientific evidences that the impacts of these emissions are harmful. Therefore, Ministry should also prescribe emission standards for these.

· There is no specific standard for Liquid Effluents. The previous CPCB standards for discharge of liquid effluents[11] were limited to only suspended solids, oil and grease, copper, iron, free available chlorine, zinc, chromium, phosphate and pH and is categorized separately based on source such as boiler blow down, cooling tower blow down, condenser cooling water and ash pond effluent. There are ample evidences which direct that there are many more toxics and chemicals which are affecting the environment and health of our countrymen and that itself demands for update of standards which should include relevant wastewater stream: e.g., from FGD system, wet ash transport, washing boiler / air preheater and precipitator, boiler acid washing, regeneration of demineralizers and condensate polishers, oil-separated water, site drainage, coal pile runoff, cooling water etc.

In the draft notification, it was expected to emphasise on the toxic metals like Mercury, Cadmium, Hexavalent Chromium, Nickel, Selenium, and other chemicals like Ammonia, Fluoride, Phenols, Phosphorus, Sulfide, Coliform bacteria (important as thermal power plants are established along with colonies) for all thermal power plant effluents. The standard for all these toxic chemicals is very much important for thermal power plants with cooling towers as well, as the achievement of ‘Zero-Discharge’ will take some time and till then we cannot do away with the hazardous impacts of the discharge.

· We also expected a standard for Radioactivity in thermal power plants. National Green Tribunal in its judgment dated 20th September, 2011 in the matter of Krishi Vigyan Arogya Sanstha & Ors vs MoEF & Ors has deliberated in details the radioactivity in coal used in thermal power plants and issued the following directions:

…The first respondent, Ministry of Environment and Forests is directed to look into the matter as to long term impacts caused by nuclear radiation from the thermal power projects, by instituting a scientific long term study involving Bhabha Atomic Research Agency or any such other recognized scientific institution dealing with nuclear radiation with reference to the coal ash generated by thermal power project (Respondent No. 3) particularly the cumulative effect of a number of thermal power project located in the area on human habitation and environment and ecology. The study shall also take into consideration the health profile of the residents within the area in which the pollutants are expected to spread from the thermal power project.

…The Ministry of Environment and Forests shall get the national standards prescribed, if not already available, from the Department of Atomic Energy, Govt. of India within a period of one year from the date of receipt of this order, as to permissible levels of nuclear radiation in residential, industrial and ecologically sensitive areas of the country

Therefore, it is a request to kindly prescribe standards for radioactivity and in compliance with the Hon’ble Tribunal’s directions.

· Temperature: The temperature rise in thermal power plant effluents is still quite higher than international standards. The present standard for new coastal thermal power plants allows upto 7°c rise (of the ambient temperature of the receiving water bodies) in temperature of condenser cooling water from inlet to the outlet of condenser; and which is relaxed upto 10° c for existing thermal power plants.

It is a request to revise the temperature rise to maximum of 3°c as suggested by World Bank[12].

· CO2 Emissions is a criterion which is completely ignored in this standard. There are enough scientific evidences that coal based thermal power plants are biggest emitter of GHGs (Green House Gases) and is now widely accepted fact that there is an urgent need to control it.

CSE’s report of 2015[13] said:

Low efficiency is directly related to high CO2 emissions. The average emission rate of plants was 1.08 tonne CO2/MWh, which is seven per cent higher than the global average and 14 per cent higher than China’s. In 2012, coal-based power generation accounted for half of India’s total CO2 emissions from fuel combustions. During 2011-12, India’s total CO2 emissions grew by six per cent which was mostly on account of coal in energy production.

There were just 13 plants in the study whose average emissions were lower than the global average. No plant conformed to the global best values. Even super critical plants in the study had emissions 35 per cent higher than the global best. It is estimated that a one percentage point improvement in efficiency can reduce CO2 emissions by 2-3 per cent. Apart from improving efficiency of existing plants, adopting state-of-the-art technologies can help achieve big cuts in emission rates.

A research paper[14] by National Physical Laboratory, Council of Scientific and Industrial Research on 86 thermal power plants in India published in 2012 states:

CO2 emissions per unit of electricity from power plants are given in Table 3B, which shows that CO2 emissions per unit of electricity range between 0.82 and 1.0 kg/kWh. These are regional average and change year to year. CO2 emissions depend upon the carbon content in the coal used and the specific coal usage (plant efficiency)Some plants are more efficient than others and the plant efficiency also varies from year to year due to maintenance . In 2009 -10, plant wise emissions of CO2 (kg/kWh) varied from 0.58 at DCR-Yamunanagar to 1.59 at Faridabad, which is an old power plant. 48 power plants emit CO2 in the range of 0.58 -1.0 kg/kWh. Three plants have CO2 emissions more than 1.4 kg/kWh. This number reflects operational inefficiency due to poor coal quality, operating conditions, maintenance, and/or plant design.

As CO2 emission is now a global threat due to its impact on climate which is linked to our growth and development as well, therefore there is very much need to cap the CO2 emissions from thermal power plants which are the highest emitter of CO2. Good news is the amount of CO2 emitted by thermal power plants can be reduced significantly by adopting newer technologies with better efficiencies and for that public policies must be developed.

For eg., most of the existing thermal power plants are sub-critical type which perform at efficiencies below 33%. The thermal efficiencies of power plants with supercritical technology can be achieved around 38.5% and ultra-supercritical technology it can be achieved more than 43%. [15]

Therefore, it is requested to kindly propose an emission standard for Indian Thermal Power Plants based on the lowest maximum CO2 emission achieved in recent past. A good recommendation will be around 0.58 kg/KWh as observed in National Physical Laboratory study which shows it is achievable.

Similar to the mandate of installing cooling towers, the new thermal power plants must be mandated with installation of ‘Ultra-Super Critical Technology’ in new thermal power plants to maximise the thermal efficiencies and minimise coal consumption.

Appreciating the emission standards for CO2 is not a common phenomenon yet, however if it is implemented, it will put our country in leading position in battle against climate change.

H. Other Important Comments

· The emission standards are not clear on the measurement criteria which will be followed like 24 hour average, yearly average and other criteria like temperature, pressure, correction of water vapour content of waste gases and O2 content. These criteria conditions of measurements must be included for clarity.

· The emission standards prescribed for general conditions may not be of help in overall reduction of pollutions in power generation hubs like Singrauli region, Korba region etc. where a large amount of coal is burnt for power generation in number of thermal power plants. Similarly, places like that of Delhi which has already several times higher pollution levels owing to heavy traffic and high density of population must be factored in. The cumulative impacts must be kept in mind for prescribing the emission standards. For eg. One thermal power of 660 MW if emits 100 mg/ Nm3, that may sound very good but what if there are number of thermal power plants with cumulative capacity of thousands of MW production? In such cases, these standards may need to be revised as final exposure to population will remain high. One of the solutions may be emission standards based on total power generation over a certain radius say 100 km and also keeping in mind the regional industrial developments. Hence, critical/key areas need to be defined and classified and special standards need to be prescribed for the power plants located in those areas.

· The emission standards alone can only do the lip service, with compliance completely lying on how much responsible the company is and commitments of the monitoring agencies. For some emissions, to achieve the desired reduction, the implementation of technologies must be given the first priority. For eg. We will not ever achieve significant reduction in SO2 and heavy metals unless there is clear mandate for installation of Flue Gas Desulphurization Units.

· One more suggestion is to also mark the standards in terms of mg/MWh. Measurement of pollutants per unit of power generation per unit time may be more realistic and practical measurement of pollutants given the different capacities of units operational in India. This will also help in implementing equal standards for all units irrespective of their size. Though, many countries follow mg/ Nm3 and it is more common, but U.S. EPA which has one of the strictest emission standards follow measurements in lb/GWh.

Concluding Remarks

It is welcome step of Ministry of Environment, Forests and Climate Change to bring out the draft notification on emission standards for coal based thermal power plants. However, the same needs many improvements and additions as discussed in this document. It is hoped that the issues and concerns discussed in this document and other such representations will be considered by the Ministry in the final notification. Any feedback and query is most welcome.

Acknowledgements

Dr. Bharat Jhunjhunwala (Economist, Environmentalist, Author)

Dr. Laxmi Goparaju (Advisor, VENHF)

Mr. Shiva Kumar Upadhyaya (Associate Director, VENHF)

Mr. Lauri Myllyvirta (Global Coal Campaigner, Greenpeace East Asia)

Ms. Parul Gupta (Lawyer, Environment)

Global Call for Climate Action Network

Download the Original Report as PDF

Annexure

Draft Notification on Emission Standard for Coal Based Thermal Power Plant (MOEFCC)- Download PDF

[1] http://envfor.nic.in/sites/default/files/draft%20Notification%20forinviting%20the%20public%20comments%20for%20the%20Coal%20BTPP.pdf

[2] http://www.scientificamerican.com/article/to-curb-climate-change-china-slows-coal-to-gas/

[3] http://www.bloomberg.com/news/articles/2015-03-24/beijing-to-close-all-major-coal-power-plants-to-curb-pollution

[4] Recent climate and air pollution impacts on Indian agriculture, PNAS, November 18, 2014, available online http://www.pnas.org/content/111/46/16319.full

[5] 'Assessment of the Mercury Content in Coal fed to Power Plants and study of Mercury Emissions from the Sector in India', Central Institute of Mining & Fuel Research (CIMFR), CSIR, Department of Science and Technology in February, 2014

[6] Supra

[7] http://www.downtoearth.org.in/content/coal-toll?page=0,1

[8] Average Flue Gas Volume for Flue gas dry 6% excess O2; at 350 Nm3/GJ is used as prescribed by Thermal Power: Guidelines for New Plants: Pollution Prevention and Abatement Handbook, WORLD BANK GROUP, Effective July 1998

[9] Report on Minimization of Water Requirement in Coal Based Thermal Power Plants, Central Electricity Authority, 2012

[10] http://www.downtoearth.org.in/content/coal-toll

[11] http://www.cpcb.nic.in/Industry-Specific-Standards/Effluent/411.pdf

[12] Environmental, Health, and Safety (EHS) Guidelines GENERAL EHS GUIDELINES: ENVIRONMENTAL WASTEWATER AND AMBIENT WATER QUALITY: International Finance Corporation & World Bank, 2007

[13] Among the Least Efficient, February, 2015: http://www.downtoearth.org.in/content/coal-toll?page=0,1

[14] "Estimates of Emissions from Coal Fired Thermal Power Plants in India" by University of South Florida and Atmospheric Sciences Division, CSIR-NPL, New Delhi and published in 2012 International Emission Inventory Conference "Emission Inventories - Meeting the Challenges Posed by Emerging Global, National, Regional and Local Air Quality Issues", Environment Protection Agency, US

[15] The Future of Coal, Massachusetts Institute of Technology, 2007 available online http://web.mit.edu/coal/The_Future_of_Coal.pdf

Correspondence of Author:

Debadityo Sinha

Mobile: +91-9540857338

Email:

Address: c/o K-86, Lower Ground Floor, Kalkaji, New Delhi-110019

Vindhyan Ecology and Natural History Foundation

Registered Office: Vindhya Bachao Secretariat, 36/30, Shivpuri Colony, Mirzapur Uttar Pradesh-231001

Website: www.vindhyabachao.org